Q1: How can I get the price? |

|

|

|

|

A1: Please provide the details of your requirements as clearly as possible. So we can send you the offer for the first time. |

|

|

|

|

For designing or further discussion, it is better to contact us with the trade manager of Alibaba, via Whatsapp, E-mail. |

|

|

|

|

Q2: How can I get a sample to check your quality? |

|

|

|

|

A2: After price confirmation, you can require samples to check our quality. Free for a stock sample to check the design |

|

|

|

|

and quality, as long as you afford the express freight. |

|

|

|

|

Q3: What about the lead time for mass production? |

|

|

|

|

A3: Within 14 days. |

|

|

|

|

Q4: What are your terms of delivery? |

|

|

|

|

A4: We accept EXW, FOB, CNF, DDU, etc. |

|

|

|

|

SUNPLAS

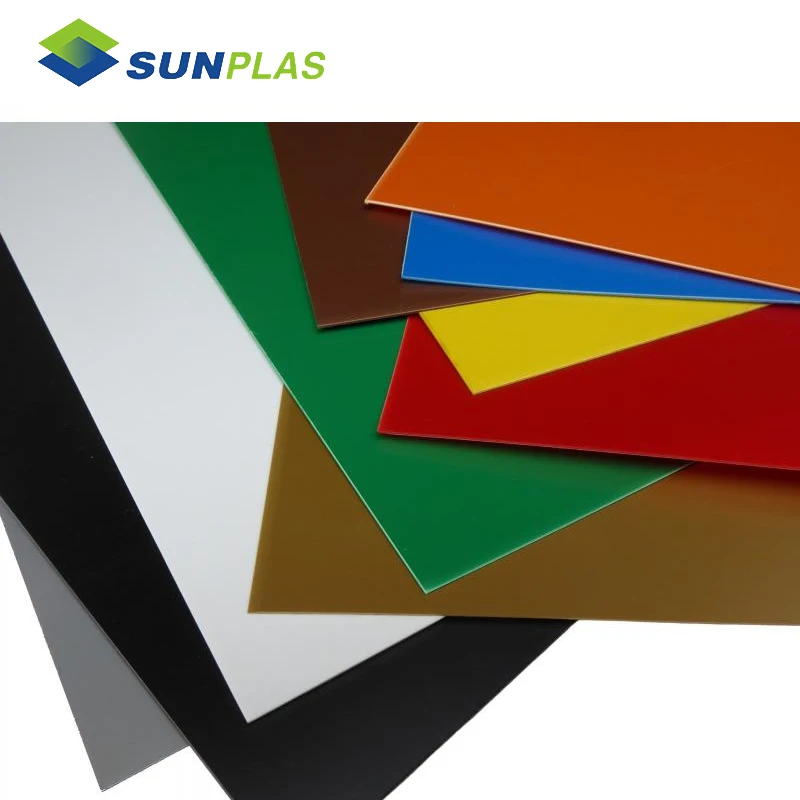

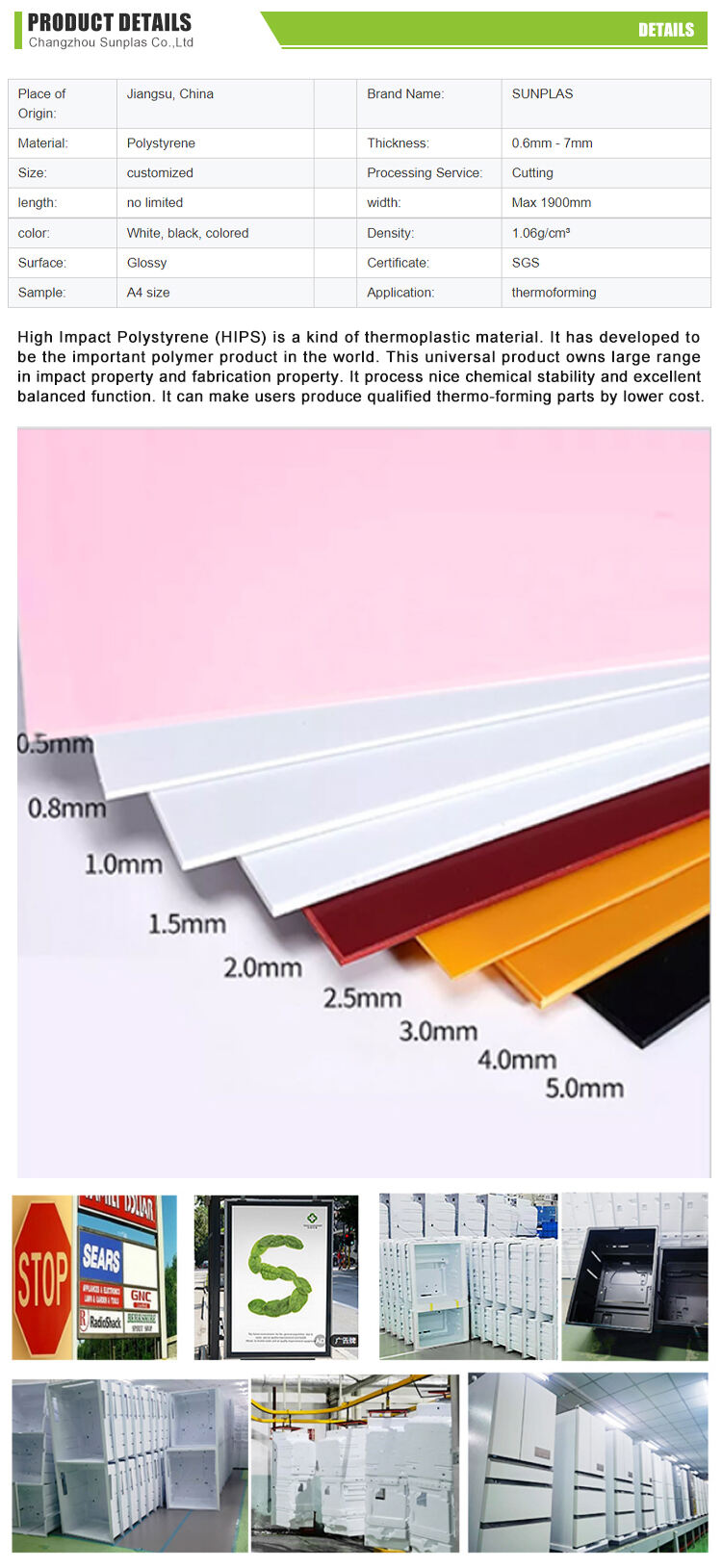

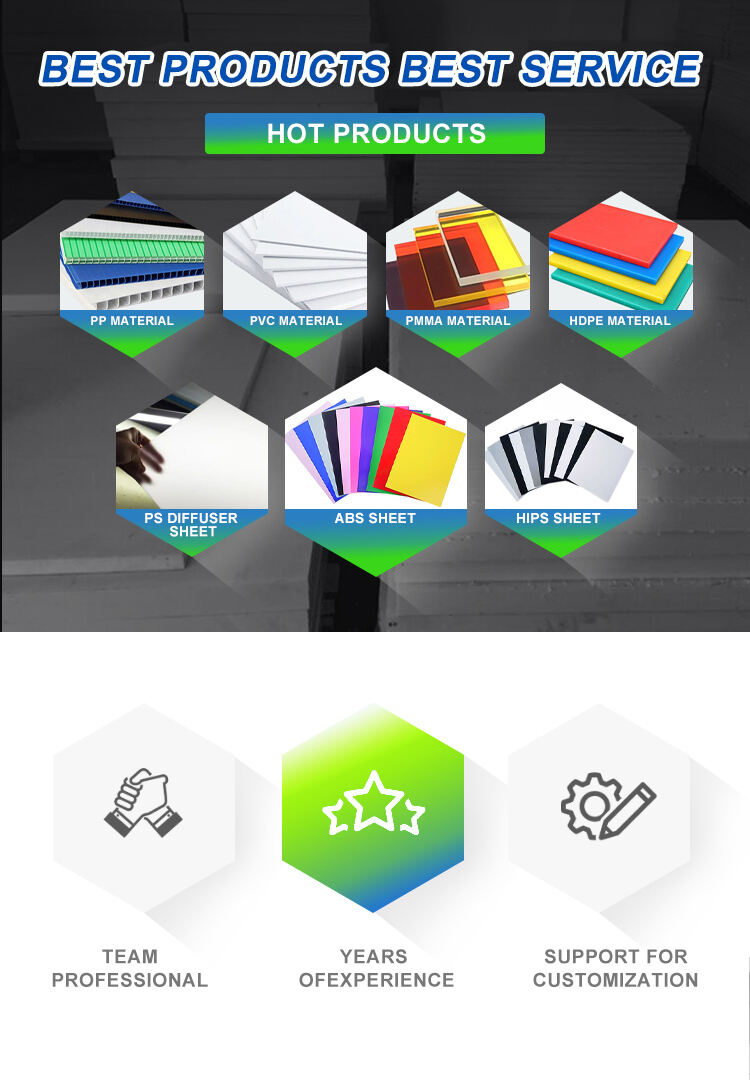

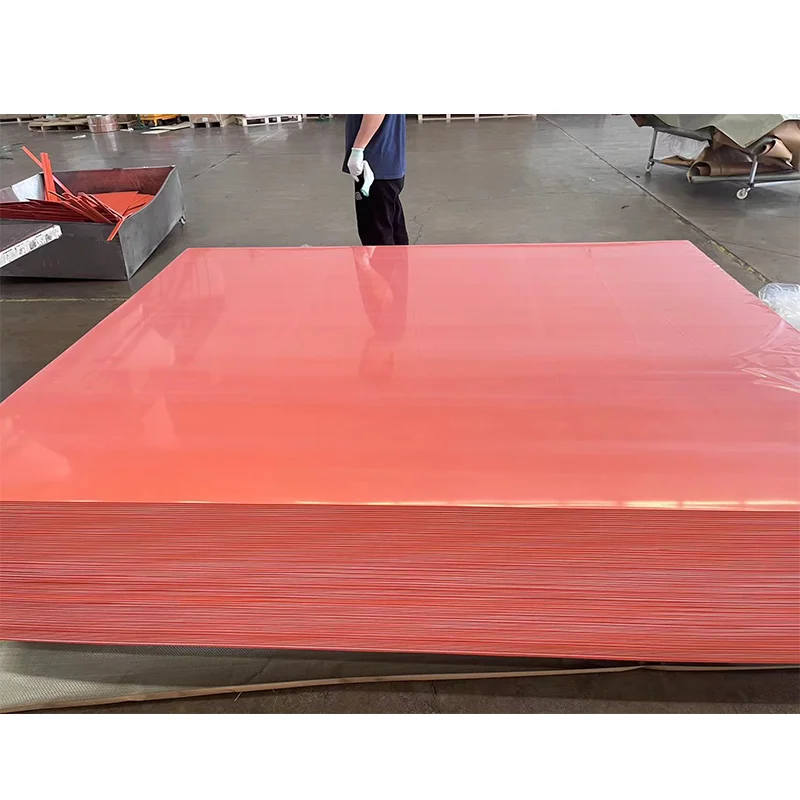

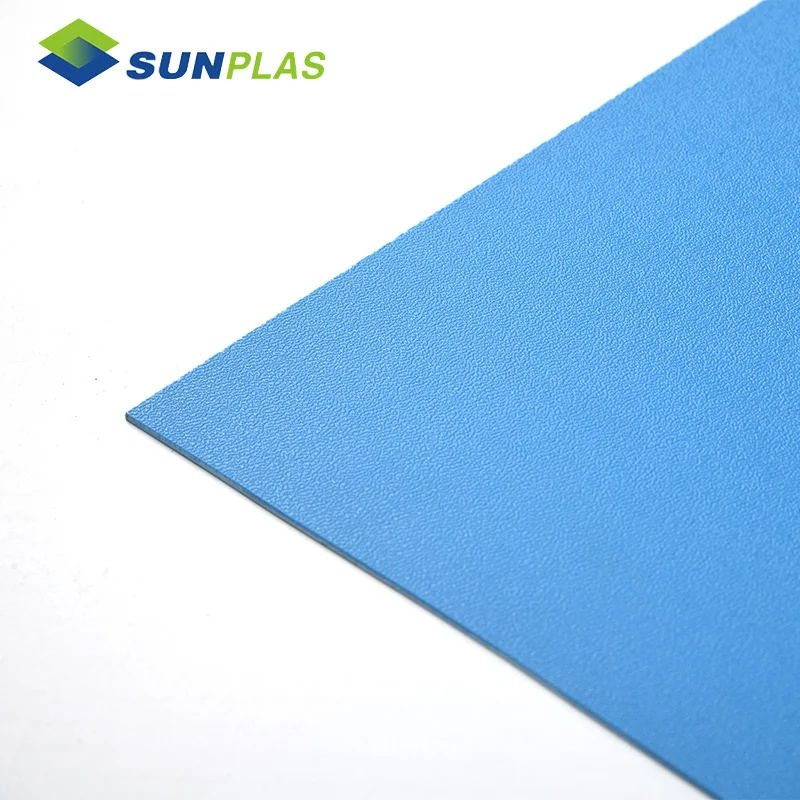

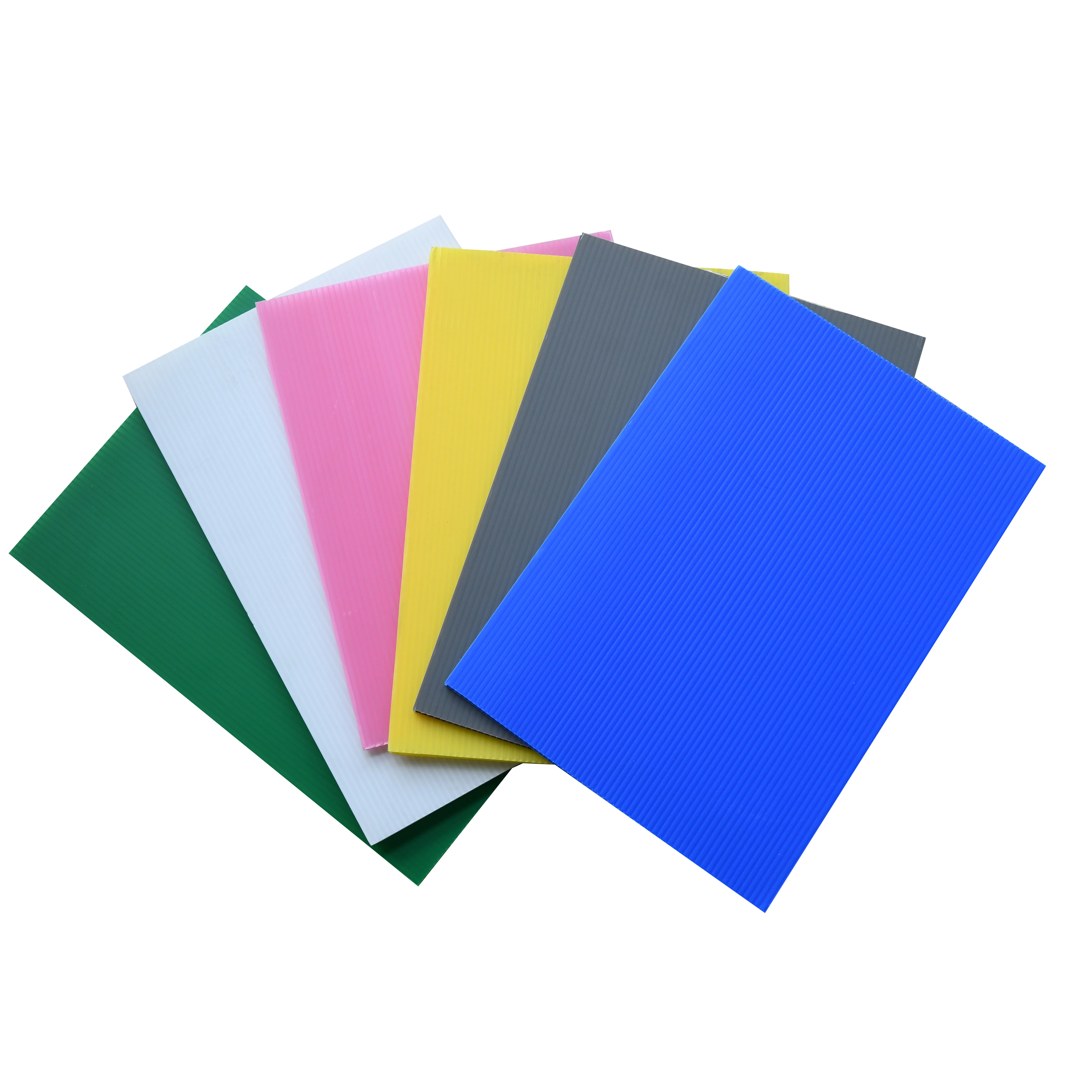

Introducing the HIPS Sheet Extrusion Line plastic and sand extruder machine polycarbonate extruder machine by the ultimate solution for your plastic extrusion needs. This versatile machine is designed to produce high-quality HIPS, polycarbonate, and sand plastic sheets. Made with precision engineering and using the latest technology, the HIPS Sheet Extrusion Line is built to last and produce flawless results.

Not hard to use and has an interface is user-friendly. It includes a high degree SUNPLAS of control on the extrusion procedure, ensuring product is consistent every time. The HIPS Sheet Extrusion Line possesses production capacity of up to 1000 kg per hour, which makes it well suited for large-scale manufacturing. The device is created to need maintenance is minimal which means that you can save both money and time on upkeep.

One of the key top features is its ability to handle a range is wide of. The device can be used to create HIPS sheets of various thicknesses, rendering it suitable for a range of applications. The extruder is polycarbonate can handle even the most challenging materials, ensuring maximum effectiveness and production.

Another standout function is its power efficiency. The machine is made using the technology is latest, including a high-efficiency motor, which ensures that power consumption is kept to a minimum. This not only helps to reduce your carbon impact but will save you money additionally on power bills.

Built to the highest standards of dependability and security. The machine comes with multiple safety features, including emergency stops and automatic shut-offs, to make that operators and technicians remain secure and safe all the time. The equipment additionally undergoes rigorous testing and official certification, that it meets all industry standards and regulations and that means you can be confident.

As one associated with the leading manufacturers of plastic extrusion machinery, SUNPLAS has a reputation for delivering top-notch and devices reliable. Their dedication to customer care and service ensures that you'll be fully supported through the lifetime of one's machine.

The HIPS Sheet Extrusion Line plastic and sand extruder machine polycarbonate extruder machine by SUNPLAS is a versatile, efficient, and reliable solution for your plastic extrusion needs. Whether you need to produce large quantities of sheet plastic or craft bespoke products, this machine has you covered. Backed by SUNPLAS's industry-leading support and service, you can be confident that the HIPS Sheet Extrusion Line will exceed your expectations.

EN

EN